INDUSTRIAL: |

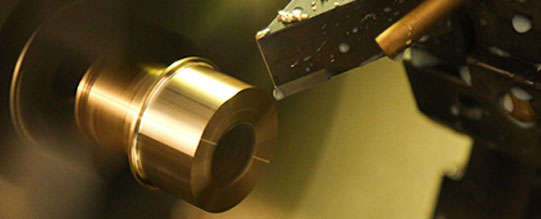

Acid Resisting Applications, Backs for Lined Journal Bearings for Locomotives, Backs for Lined Journal Bearings for Passenger Cars, Bearings, Freight Car Bearings, General Service Bearings for Moderate Pressure, Industrial Centrifuges, Low Friction, Moderate Pressure Bushings, Machine Parts, Pump Bodies for Acid Mine Water, Pump Impellers for Acid Mine Water, Pumps, Railroad Applications, Railroad Engine Casings, Wearing Material for Rod Bushings, Wearing Material for Shoes, Wearing Material for Wedges. |

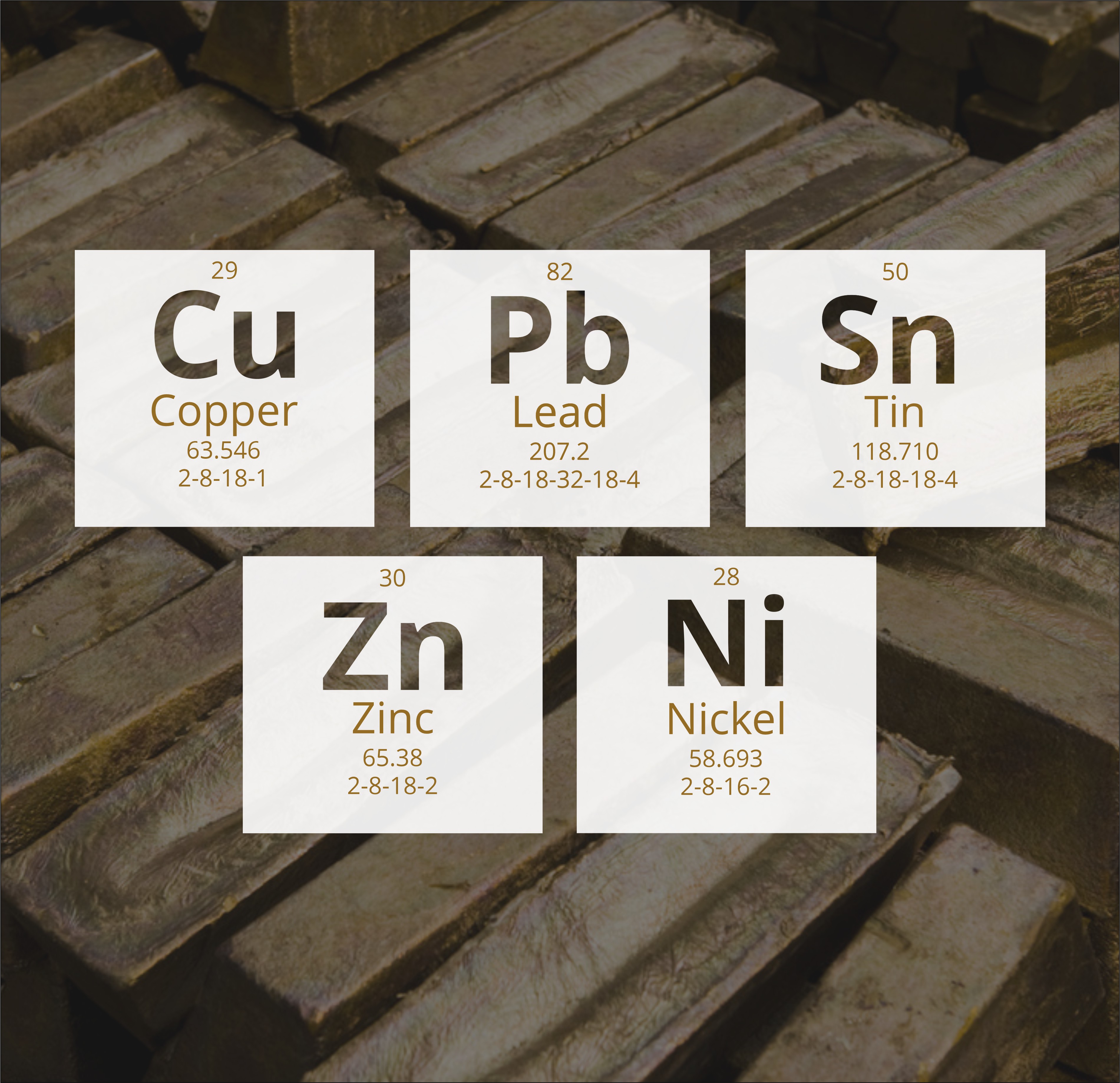

Corrosion Resistance, Corrosion Resistance to Brackish Water, Corrosion Resistance to Many Industrial Chemicals, Corrosion Resistance to Numerous Environments, Low Coefficient of Friction, Wear Resistance, Anti-Seizing Properties, Thermal Conductivity, Excellent Machinability, Pressure Tightness. |

MARINE: |

Large Bearings for Ships. |

Corrosion Resistance, Corrosion Resistance to Brackish Water, Corrosion Resistance to Numerous Environments, Anti-Seizing Properties, Low Coefficient of Friction, Wear Resistance, Good Machinability. |