INDUSTRIAL: |

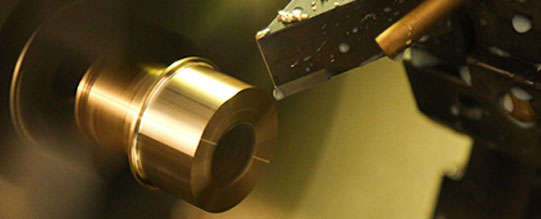

Acid Resistant Pumps, Bearing Liners, Bearings, Bushings, Gears, High Strength Clamps, Hot Mill Guides, Hydrant Parts, Large Gear Parts, Mild Alkali Applications, Pickling Equipment, Pickling Tanks, Plungers, Pump Parts, Thrust Pads, Valve Bodies, Valve Seats, Valves, Wear Plates, Welding Jaws, Worm Wheels, Worms. |

Corrosion Resistance (Excellent), Corrosion Resistance to Acids, Corrosion Resistance to Fresh Water, Corrosion Resistance to Saline Solutions, Wear Resistance, Machinability Good, High Strength, Thermal Conductivity, Retains Strength at Elevated Temperatures, Corrosion Resistance to Brackish Water. |

MARINE: |

Covers for Marine Hardware, Marine Engines, Marine Hardware, Propellers. |

Appearance, Corrosion Resistance (Excellent), Corrosion Resistance to Fresh Water, Corrosion Resistance to Salt Water, High Strength, Corrosion Resistance to Brackish Water, Wear Resistance, Fatigue Properties, Corrosion Resistance to Saline Solutions, Retains Strength at Elevated Temperatures. |