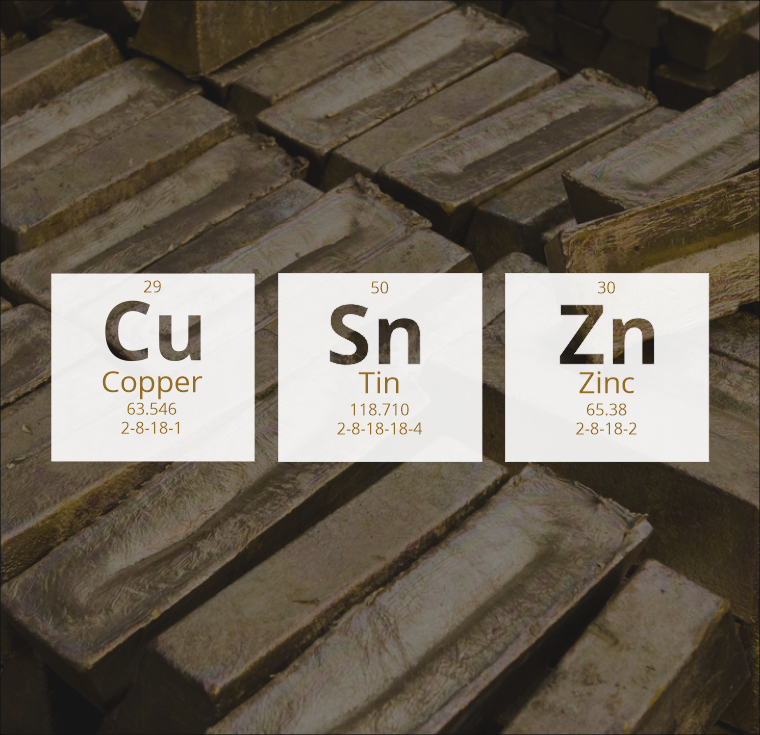

BUILDERS HARDWARE: |

Clamps. |

Corrosion Resistance to Numerous Environments, Moderate Strength. |

BUILDING: |

Heavy Construction Equipment. |

Corrosion Resistance, Wear Resistance, Moderate Strength, Pressure Tightness up to 260 C. |

ELECTRICAL: |

Connectors. |

Electrical Conductivity, Thermal Conductivity, Corrosion Resistance to Numerous Environments, Moderate Strength. |

FASTENERS: |

Nuts. |

Corrosion Resistance, Moderate Strength. |

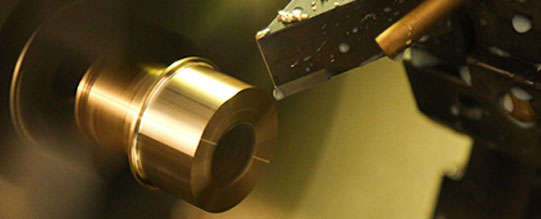

INDUSTRIAL: |

Bearings, Expansion Bearings, Finishing Dies for Wood Pulp Industry, Gear Blanks, Gears, Piston Rings, Pump Bodies, Pump Impellers, Seal Rings, Valve Bodies, Valves, Worm Gears. |

Corrosion Resistance, Low Co-efficient of Friction, Wear Resistance, Moderate Strength, Corrosion Resistance to Fresh Water, Corrosion Resistance to Numerous Environments, Corrosion Resistance to Saline Solutions, Pressure Tightness up to 260 C, Good Machinability. |

PLUMBING: |

Steam Fittings, Water Conditioners. |

Corrosion Resistance to Numerous Environments, Moderate Strength, Pressure Tightness up to 260 C, Corrosion Resistance to Fresh Water, Corrosion Resistance to Saline Solutions. |