DESCRIPTION

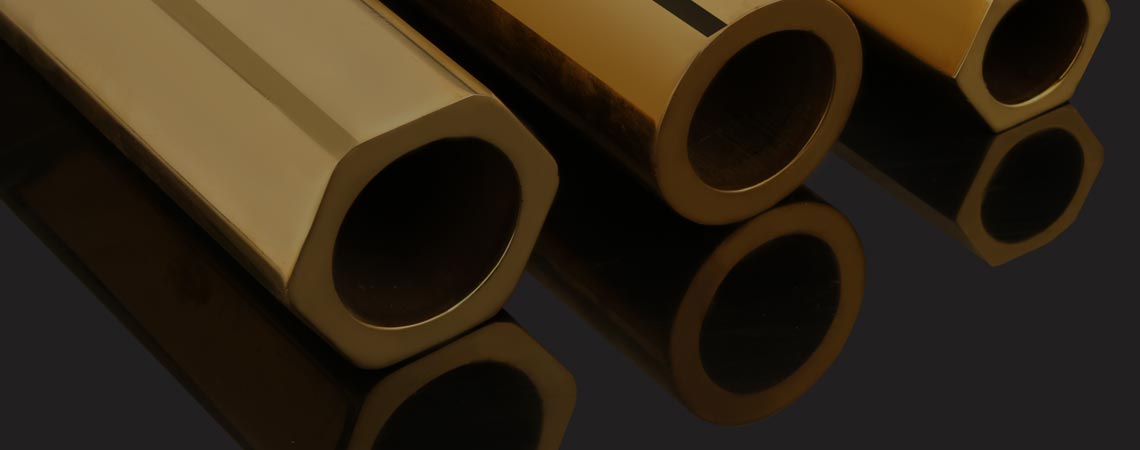

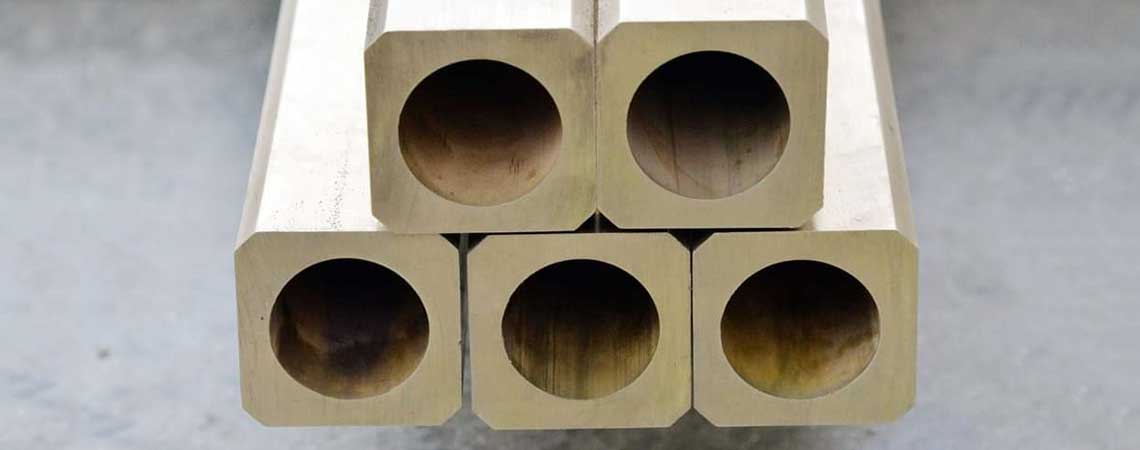

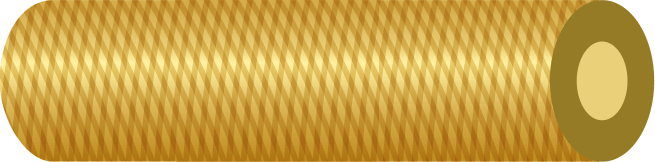

Hollow extruded bars, also known as extruded tubes or hollow profiles. hollow extruded bars offer a combination of lightweight design, customizable shapes, and material versatility. They are widely used in various industries for applications that benefit from their unique tubular structure and the specific properties of the chosen material.

In designing a component, it is very essential to take the production costs into consideration to keep it as low as possible while maintaining the quality. Although hollow extrusions cost more per unit weight than solid bars, this is frequently offset by the saving in drilling and reduction of swarf. Using modern production techniques the eccentricity of hollows is minimal.

We, at Adinath, produce Hollow Rods in Round, Hex and Squares shapes which we can offer to our customers to reduce the production costs. Standard shapes of hollow bar are available which often proves to be a more cost-effective choice for the manufacture of hollow components.