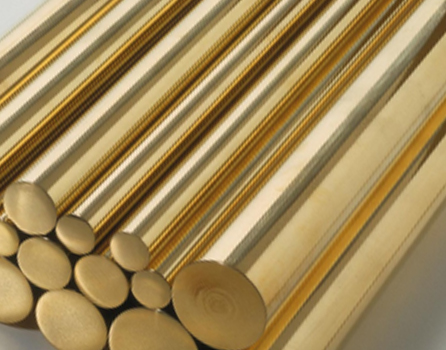

DESCRIPTION

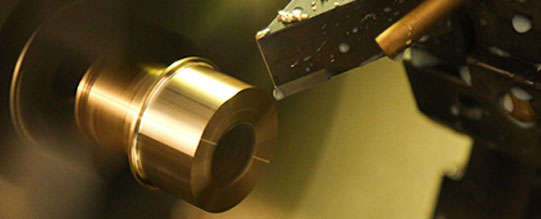

Naval Brass, as the name indicates, were originally developed for sea water service applications since it is a hard and durable material that provides excellent corrosion resistance, hot workability, and hot forgeability. Majority of the grades falling under Naval Brass are considered Lead Free products with Lead content around 0.20%. The usage of Naval Brass is not limited to Marine products, but also in bushings, valve stems, fasteners and wear strip because of its higher tensile strength and wear resistance properties. Tin is used in Naval Brass which slow down dezincification and can also control the rate of corrosion to allow acceptable practical service lives for marine products.

C46400 is a type of Copper-Zinc-Tin alloy where the addition of Tin provides good strength and rigidity. The addition of tin also improves the corrosion resistance in seawater at higher than normal temperatures, specially against dezincification. The alloy is also noted for its resistance to wear, fatigue, galling, and stress corrosion cracking. Apart from this properties, C46400 is also known for its hardness and is suitable for a wide range of fresh and seawater applications. C46400 is slightly yellow then Architectural Bronze with good colour match for decorative and architectural products.