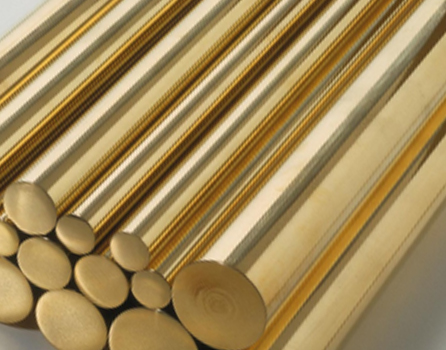

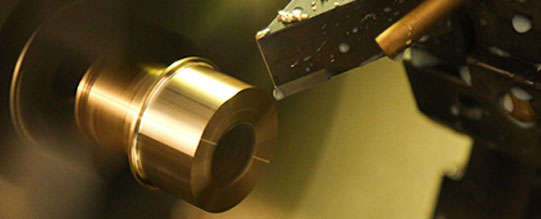

DESCRIPTION

Manganese Bronze comes from a family of High strength copper based alloys which includes Manganese as an alloying agent with additions of Iron, Aluminium, Zinc, Lead and sometimes Nickel or Silicon. It has exceptionally high strength as compared to normal brass and therefore commonly known as High Tensile Brass, High Tensile Manganese Bronze, High Strength Brass or Manganese Aluminium Bronze. Like Aluminium Bronzes, High Tensile brasses offers a variety of properties in the form of higher strength levels, non-corrosive properties, improved hardness, yield strength and tensile strength. Some of the High Tensile Brasses are known to have excellent hot forming properties and can be used in environments where soldering, welding or brazing is required.

C67600 is a Manganese Leaded Bronze alloy which is widely known for its higher strength and corrosion resistance properties. This alloys can be hot worked and has good soldering and brazing properties.