DESCRIPTION

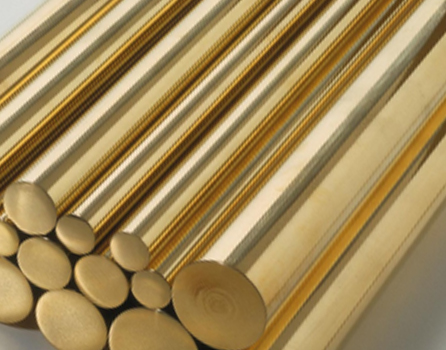

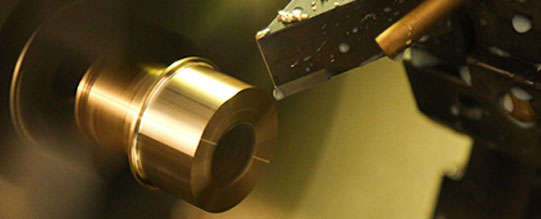

Leaded brasses set the standard by which the machinability of other materials is judged and is also available in a very wide variety of product forms and sizes to allow minimum machining to finished dimensions. Leaded brass is used for its excellent machinability, good strength and atmospheric corrosion resistance. While all brasses are intrinsically easy to machine, the addition of small amounts of lead to brasses further improves this property. Lead acts as a lubricant decreasing the friction coefficient between the tool and the material, creating discontinuities that promote the chip fragmentation, reducing the cutting force and the tool wear rate. Brasses can contain up to 3.5 percent in lead contents, and are classified as low, medium, or high-leaded.

CW602N is a special alloy also known as leaded arsenical brass which contains extemely low dezincification values. CW602N offers good machinability with improved strength levels and can be easily hot forged. It is a preferred choice to make Fitting parts in contact with water where there are stringent requirements for dezincification.