AUTOMOTIVE: |

Weld Guns. |

Thermal Conductivity, Corrosion Resistance, High Strength. |

BUILDERS HARDWARE: |

Brackets. |

Corrosion Resistance, High Strength, Toughness. |

ELECTRICAL: |

Electrical Hardware. |

Electrical Conductivity, Thermal Conductivity, Corrosion Resistance, High Strength. |

INDUSTRIAL: |

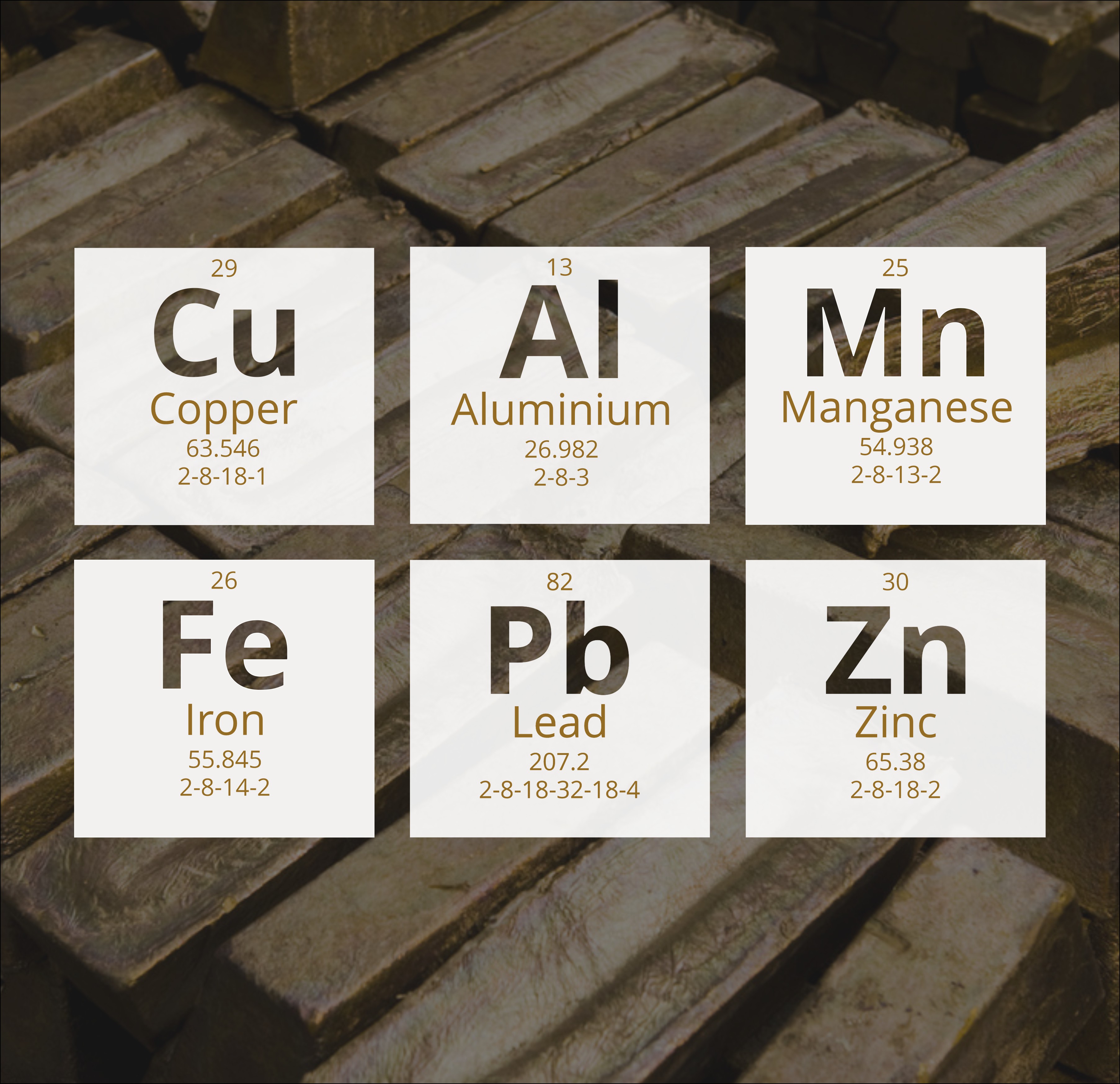

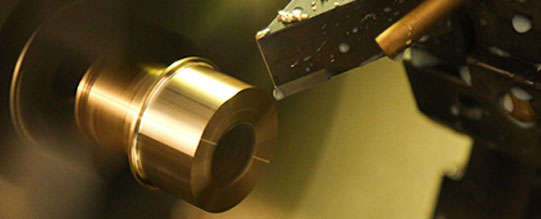

Compressors, Forming Dies for Wood Pulp Industry, Frames, Gears, Hooks, Lever Arms, Machinery, Machinery Parts (Substituted for Steel and Malleable Iron), Machinery Parts requiring High Strength, Pressing Dies for Wood Pulp, Struts, Wear Rings for Pressing Dies for Wood Pulp Industry. |

Corrosion Resistance, High Strength, Toughness, Wear Resistance, Excellent Machinability (Free Machining), Corrosion Resistance to Fresh Water, Corrosion Resistance to Salt Water, Thermal Conductivity. |

MARINE: |

Boat Parts, Clamps, Covers for Marine Hardware, Propellers for salt and fresh water, Rudders. |

Corrosion Resistance, Corrosion Resistance to Salt Water, High Strength, Toughness, Appearance, Corrosion Resistance to Saline Solutions, Ductility. |