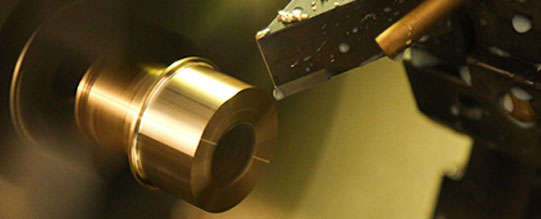

INDUSTRIAL: |

Aircraft Parts, Balls, Bearings, Bushings, Cams, Condenser Tube for Power Stations and Desalting Units, Corrosion Resistant Articles, Gears, Heat Exchanger Flanges, Hydraulic Bushings for Earth Moving Equipment, Plunger Tips, Pump Parts, Pump Shafts, Shafting, Structural Members, Tanks, Valve Balls, Valve Guides, Valve Seats, Welded Piping Systems. |

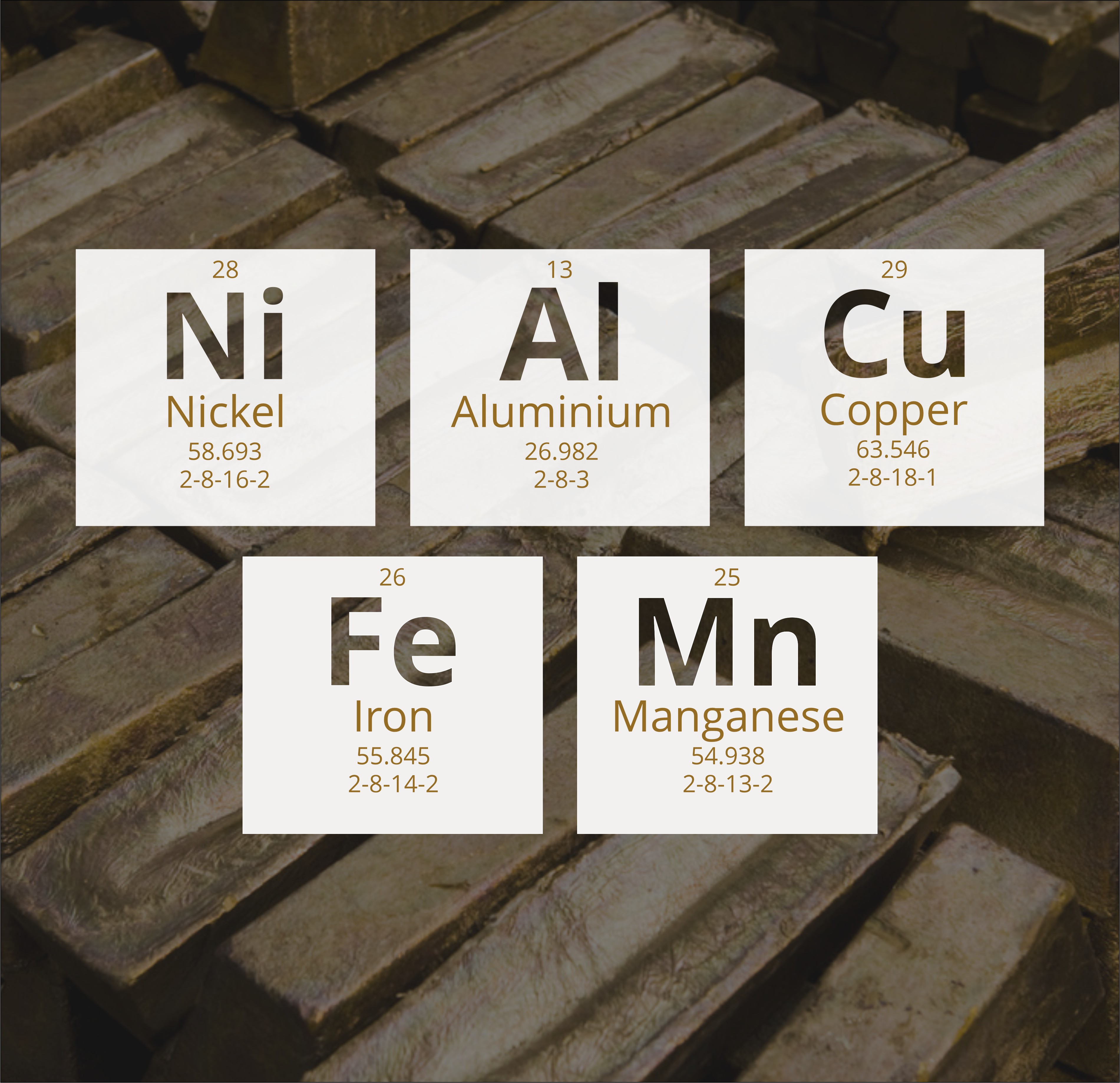

Corrosion Resistance, Wear Resistance, Impact Resistant, High Strength, Corrosion Resistance to Chemicals, Corrosion Resistance to Non Oxidizing Acids, Corrosion Resistance to Numerous Environments, Corrosion Resistance to Salt Water, Galling Resistance, Resistant to Abrasive Wear, Resistant to Adhesive Wear Toughness, Heavy Load Strength, Thermal Conductivity, Weldability, Impact Resistant, Cavitation Corrosion Resistance, Erosion Corrosion Resistance, Pitting Corrosion Resistance, Resistance to Corrosion by a broad variety of Corrosive Media. |

MARINE: |

Bolts, Nuts, Propellers, Pump Parts, Ship Propellers. |

Corrosion Resistance, Corrosion Resistance to Fresh Water, Corrosion Resistance to Numerous Environments, Corrosion Resistance to Salt Water, Impact Resistant, High Strength, Weldability. |