INDUSTRIAL: |

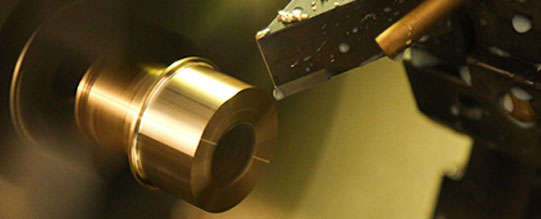

Bearings. |

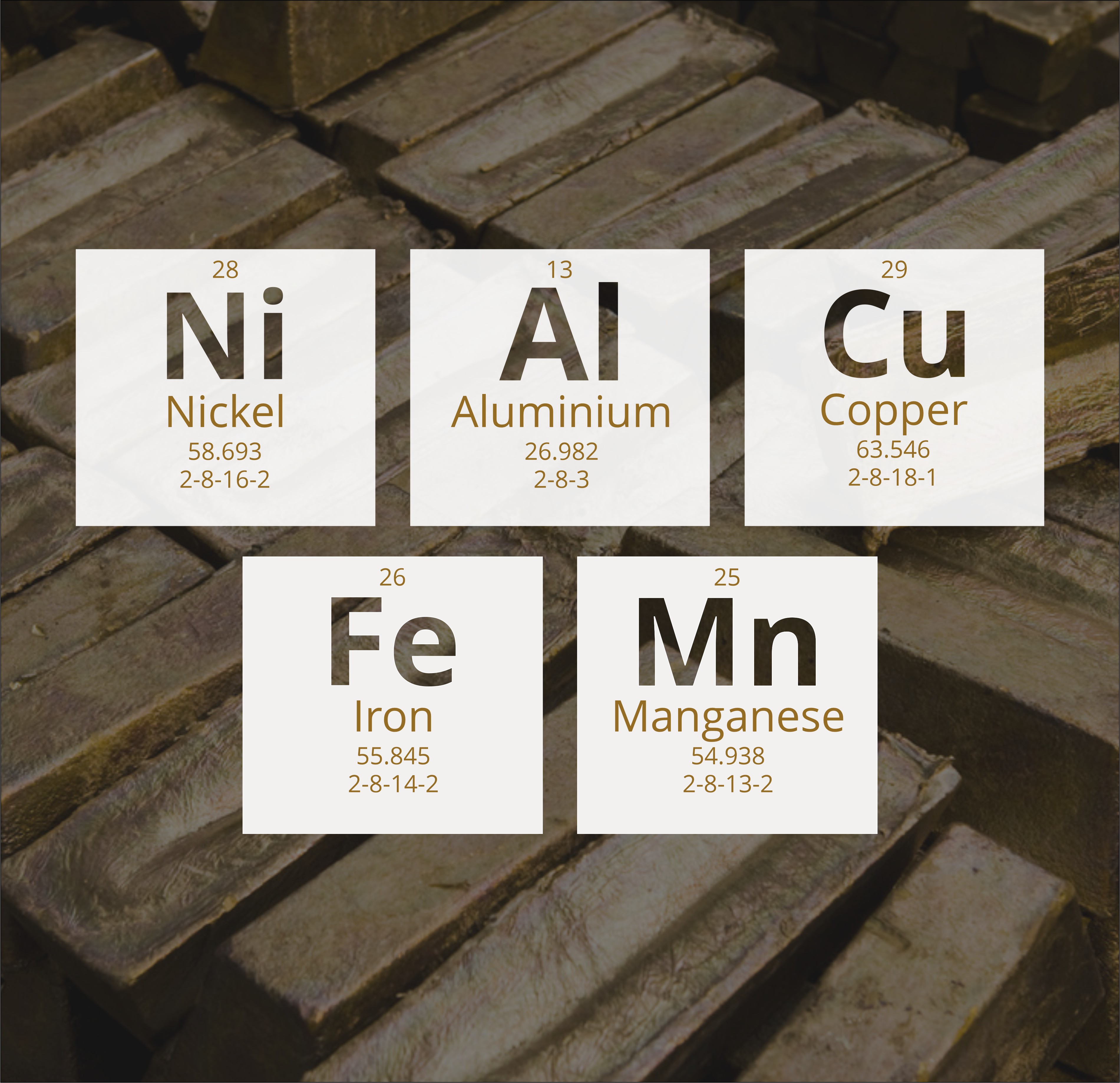

Corrosion Resistance, Wear Resistance, Fatigue Strength, High Strength, Retains Strength at Elevated Temperatures. |

|

Gears. |

Corrosion Resistance, Wear Resistance, Fatigue Strength, High Strength, Retains Strength at Elevated Temperatures. |

|

Pickling Baskets. |

Corrosion Resistance, Corrosion Resistance to Acids, Wear Resistance, High Strength, Retains Strength at Elevated Temperatures. |

|

Pickling Hooks. |

Corrosion Resistance, Wear Resistance, Fatigue Strength, High Strength, Retains Strength at Elevated Temperatures. |

|

Spur Gears. |

Corrosion Resistance, Wear Resistance, Fatigue Strength, High Strength, Retains Strength at Elevated Temperatures. |

|

Valve Components. |

Corrosion Resistance, Wear Resistance, Fatigue Strength, High Strength, Retains Strength at Elevated Temperatures. |

|

Worms. |

Corrosion Resistance, Corrosion Resistance to Acids, Wear Resistance, High Strength, Retains Strength at Elevated Temperatures. |