CONSUMER:  |

Sculpture. |

Appearance, Corrosion Resistance, Weldability. |

ELECTRICAL: |

Motors, Rotor Bar, Pole Line Hardware. |

Brazability, Electrical Resistivity, Electrical Conductivity, Thermal Conductivity, Corrosion Resistance, High Strength. |

FASTENERS: |

Bolts, Burrs, Clamp, Cotter Pins, Hinges, Nails, Nuts, Rivets, Screws. |

Corrosion Resistance, High Strength, Corrosion Resistance to Petrochemicals, Appearance, Formability. |

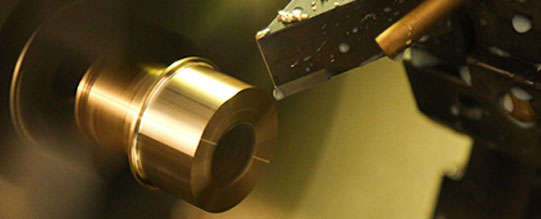

INDUSTRIAL: |

Bearing Plates, Bushings, Butts, Cable, Channels, Chemical Equipment, Doctor Blades, Paper Industry, Heat Exchanger Tubes, Hydraulic Pressure Lines, Kettles, Oil Refinery Plumbing Tube, Piston Rings, Pressure Vessels, Screen Cloth, Screen Plates, Shafting, Tanks, Wear Plates, Welded Pressure Vessels, Welded Tanks. |

Corrosion Resistance, Galling Resistance, Wear Resistance, High Strength, Formability, Corrosion Resistance to Fresh Water, Corrosion Resistance to Paper Industry Chemicals, Corrosion Resistance to Salt Water, Non-Sparking, Weldability, Corrosion Resistance to Petrochemicals, Wear Resistance, Moderate to High Strength, Solderability. |

MARINE: |

Hardware, Propeller Shafts. |

Appearance, Corrosion Resistance, Corrosion Resistance to Fresh Water, Corrosion Resistance to Salt Water, High Strength, Wear Resistance. |