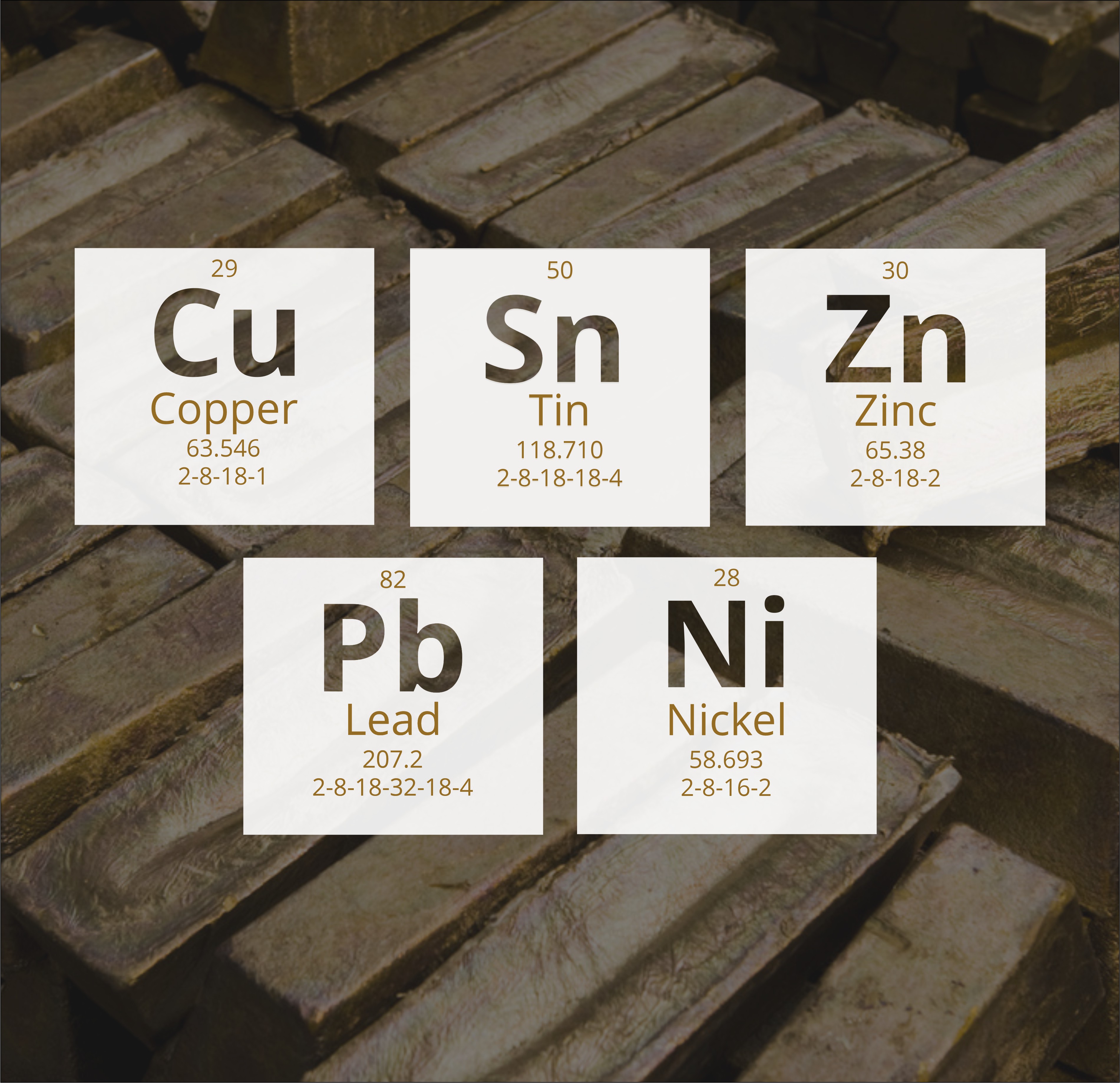

ARCHITECTURE: |

Ornamental Fixtures. |

Appearance, Castability, Corrosion Resistance, Moderate Strength. |

BUILDERS HARDWARE: |

Hardware. |

Appearance, Corrosion Resistance, Moderate Strength. |

BUILDING: |

Cooling Equipment, Heating Equipment, Lightning Protection, Trowels for Cement Working. |

Thermal Conductivity, Corrosion Resistance, Moderate Strength, Electrical Conductivity, Oxidation Resistance, Wear Resistance. |

ELECTRICAL: |

Electrical Equipment,Electrical Hardware, Switches. |

Electrical Conductivity, Thermal Conductivity, Corrosion Resistance, Moderate Strength, Corrosion Resistance to Fresh Water. |

FASTENERS: |

Large Hold Down Screws. |

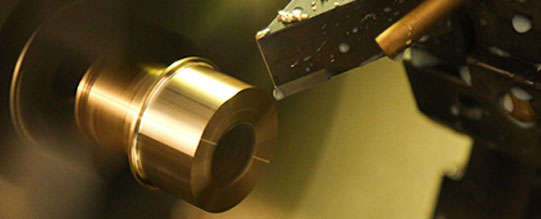

Corrosion Resistance, Good Machinability, Moderate Strength. |

INDUSTRIAL: |

Air Actuators, Bearing Segments for Steel Industry, Bearings, Bushings, Couplings, Furnaces, Handles for Dental Equipment, Impellers, Low Pressure Valves, Pressure Blocks for Steel Industry, Printing Presses, Pump Fixtures, Pump Parts, Pumps, Rings, Small Gears, Transducer Housings, Valve Bodies, Valve Bodies for the Water Meter Industry, Valves, Valves for the Water Meter Industry. |

Corrosion Resistance, Good Machinability , Moderate Strength, Pressure Tight, Wear Resistance, Thermal Conductivity, Appearance, Ductility. |

MARINE: |

Marine Products, Parts for Boats. |

Corrosion Resistance, Corrosion Resistance to Salt Water, Wear Resistance, Moderate Strength, Corrosion Resistance to Salt Water. |

PLUMBING: |

Faucets, Fixtures, Pipe Fittings. |

Appearance, Corrosion Resistance, Moderate Strength, Wear Resistance. |