×

☰

Nickel Aluminium Bronze

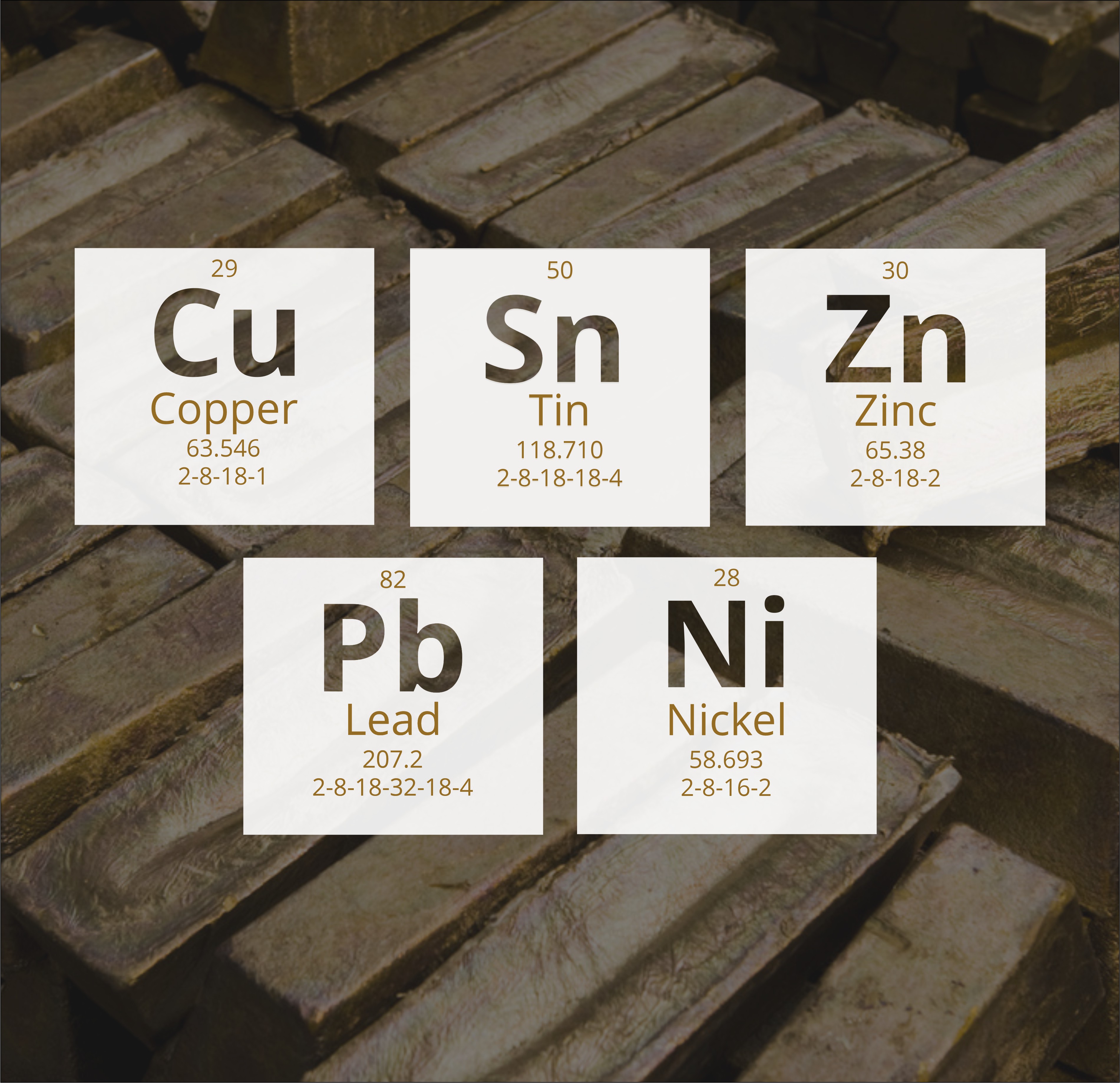

Manganese Brronze HighTensile Brass

Tin Bronze

Silicon Bronze

Leaded Tin Bronze

Brass Ingots

Aluminium Bronze Ingots

Silicon Brass

Phosphor Bronze

Gum Metal / Red Brass / Bronze

Quality

Our journey

Infrastructure

Core Purpose & Values

Human Assets / Resource

Management

Capabilities

Environment & CSR

Media Center

Contact Us