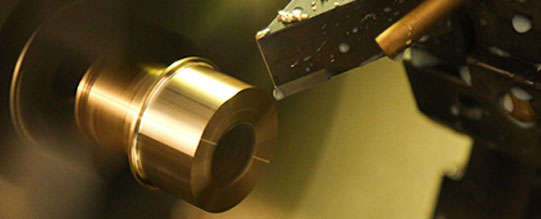

INDUSTRIAL: |

Backs for Lined Bearings, Bearings for corrosion, lubrication or pressure, Bushings for corrosion, lubrication or pressure, Cam Bushings for Diesel Engines, Crankshaft Main Bearings, Deep Well Pump Bowl Bushings, Deep Well Pump Line Shaft Bearings, Electric Motor Bearings, Flow Monitor Valves, Guide Bushings for Piston Rods, Guide Bushings for Valves, Hydraulic Gland Seals, Locomotive Bearing Parts, Main Bearings for Presses, Oil Field Equipment, Piston Pin Bearings, Pump Sleeves, Rod Bushings, Rolling Mill Bearings, Seals, Sleeve Bushings (for cranes, etc.), Steel Mill Bushings, Wrist Pin Bushings. |

Corrosion Resistance, Wear Resistance, Good Machinability, Corrosion Resistance to Brackish Water, Corrosion Resistance to Many Industrial Chemicals, Corrosion Resistance to Numerous Environments, Anti-Seizing Properties, Low Coefficient of Friction, Excellent Machinability, Resistance to Pounding, Tolerance for Dirt and Grit. |