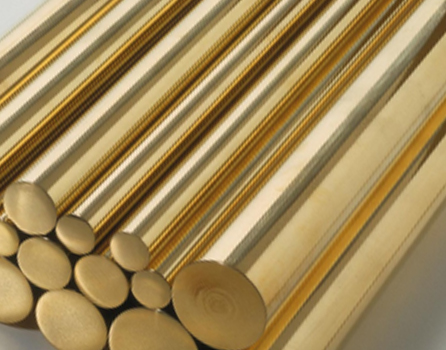

Free Cutting Brass is commonly known as leaded brass which contains 56 to 63 % of Copper, 2 to 3.50 % Lead, and balance Zinc. Free Machining Brass refers to the alloys "Machinability". Machinability is a catch term that measures the ease with which a metal can be drilled, turned, cut or machined. Free machining brass sets the standard by which the machinability of other alloys is measured. The usage of Free Cutting Brass ensures cost-effectiveness via the application of close-tolerance manufacturing techniques and reducing tooling costs. Apart from these benefits, the high value of this alloy's scrap can be used to reduce the production costs significantly.

IS 319 Free Cutting Grade I is the standard grade across the Indian Subcontinent for Free Machining Brass. It is widely used owing to its suitability for high-speed machining operations and also for the manufacturing of complex parts. The ease of brazing/soldering, high corrosion resistance combined with its good strength, and a machinability rating of 100% makes it an ideal choice of application in a wide range of brass components throughout the industry.

IS:319 Grade-I

Specification Document

| ELEMENT | Copper | Iron | Zinc | Lead | Other Impurities |

|---|---|---|---|---|---|

| Min (%) | 56.00 | - | Balance | 2.00 | - |

| Max (%) | 59.00 | 0.35 | 3.50 | 0.70 |

Size Range: Dia 5 mm up to 120 mm

Size Range: A/F 5 mm up to 100 mm

Size Range: A/F 5 mm up to 90 mm

Size Range: A/F 6 x 8 mm up to 100 x 50 mm

Outer Diameter : In Round & Hex

Size Range : 24 mm up to 110 mm

Outer Diameter : In Square

Size Range : 24 mm up to 90 mm

Inner Diameter (Round):

Size Range : 12 mm up to 80 mm

According to customer drawing

Length: Up to 4 Meters

Delivery Condition: As Extruded or Cold Drawn

Straight Knurling & Cross Knurling will be available upon shape & size Feasibility of Brass Rod

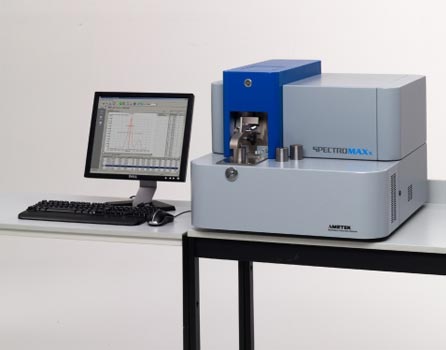

AEPL's Quality Management System ensures documented process controls from start to finish. Material identification and inspection are carried out in all stages of production.

Chemical check by Handheld analyzers.

Pyrometers and Optical Emission Spectrometer

Identification by Punching Heat Codes

Tag allocation by Heat Number/Order codes as it moves down the production line

Mechanical Testing - Tensile Strength, Elongation and Hardness

Handling, Processing and Packaging Procedures to ensure delivery in prime condition

All bars manufactured at AEPL are supplied with full certifications helping us to deliver the exact specification demanded by our specific customer base.

AEPL manufactures and supplies Copper Alloys Extruded Bars to Domestic as well as International Markets. Our customer base has a key advantage since our Foundries, Laboratories, Extrusion Mill, Shell Mouldings and CNC Machine shop are all located on a single site, which eliminates waste and allows excellent quality control at each stage. Our ability to reclaim swarf and machined chips allows us to offer competitive pricing for the parts that we either extrude or cast. For further details, please visit the below link.

| Range (mm) | UTS Min (Mpa) | PS Min (Mpa) | Elongation Min (%) | Hardness (HRB) | ||

|---|---|---|---|---|---|---|

| Over 6 to 12 Inclusive | 405 | - | 4 | 68 to 82 | ||

| Over 12 to 25 Inclusive | 395 | - | 6 | 66 to 81 | ||

| Over 25 to 50 Inclusive | 355 | - | 12 | 61 to 76 | ||

| Over 50 to 75 Inclusive | 325 | - | 17 | 52 to 72 | ||

| Range (mm) | UTS Min (Mpa) | PS Min (Mpa) | Elongation Min (%) | Hardness (HRB) | ||

|---|---|---|---|---|---|---|

| Over 6 to 12 Inclusive | 405 | - | 4 | 68 to 82 | ||

| Over 12 to 25 Inclusive | 395 | - | 6 | 66 to 81 | ||

| Over 25 to 50 Inclusive | 355 | - | 12 | 61 to 76 | ||

| Over 50 to 75 Inclusive | 325 | - | 17 | 52 to 72 | ||

| Range (mm) | UTS Min (Mpa) | PS Min (Mpa) | Elongation Min (%) | Hardness (HRB) | ||

|---|---|---|---|---|---|---|

| Over 6 to 12 Inclusive | 405 | - | 4 | 68 to 82 | ||

| Over 12 to 25 Inclusive | 395 | - | 6 | 66 to 81 | ||

| Over 25 to 50 Inclusive | 355 | - | 12 | 61 to 76 | ||

| Over 50 to 75 Inclusive | 325 | - | 17 | 52 to 72 | ||

| Range (mm) | UTS Min (Mpa) | PS Min (Mpa) | Elongation Min (%) | Hardness (HRB) | ||

|---|---|---|---|---|---|---|

| Over 6 to 12 Inclusive | 405 | - | 4 | 68 to 82 | ||

| Over 12 to 25 Inclusive | 395 | - | 6 | 66 to 81 | ||

| Over 25 to 50 Inclusive | 355 | - | 12 | 61 to 76 | ||

| SOLDERING | BRAZING | MACHINABILITY RATING |

|---|---|---|

| EXCELLENT | GOOD | 100 |

| product category | DESCRIPTION |

|---|---|

ARCHITECTURE : |

Terrazzo Strip. |

AUTOMOTIVE : |

Fluid Connectors, Sensor Bodies, Thermostat Parts, Threaded Inserts for Plastic. |

BUILDERS HARDWARE: |

Fittings, Hardware, Lock Bodies. |

CONSUMER :  |

Hot Combs (to Straighten Hair). |

FASTENERS : |

Bolt, Nuts, Screws. |

INDUSTRIAL: |

Adapters, Automatic Screw Machine Parts, Faucet Components, Fluid Connectors, Gauges, Gears, Nozzles, Pinions, Pneumatic Fittings, Screw Machine Products, Unions, Valve Seats, Valve Trim. |

PLUMBING: |

Faucet Seats, Faucet Stems, Plumbers' Brass Goods, Plumbing Fittings. |